No. 59 HIDDEN CONTAMINATION March 2008

Every rule, directive, regulation, instruction and procedure tells you to periodically inspect the underwing nozzle strainer and remove any collected contamination. Some directives tell you to inspect the contamination to see whether it indicates equipment failure. Rubber particles (black debris) indicate problems in the hose. Metallic particles indicate equipment failure. Sand, bits of wiping rags and other debris tell you that someone has been careless.

So it is obvious that nozzle strainer inspections are important, but how you do it is the point we want to make in this GamGram.

Recently a large quantity of contamination was found in a hose when none had been found in the underwing nozzle strainer. This occurred even though the nozzle strainer was inspected immediately after the aircraft had been fueled. Due to the fact that the nozzle was in a vertical position and the dirt was heavy, gravity allowed it to fall "down" when the flow stopped. Flow had carried the parti les into the strainer, but when flow stopped, the particles fell back into the hose. This process can happen over and over again. This is what the title of this GamGram means - Hidden Contamination,.

To avoid this problem, the nozzle strainer should be inspected only after flow has taken place with the nozzle in a horizontal position. However, even though you may follow this instruction, you can still see no dirt in the strainer if you hold the nozzle up above the horizontal while you open it. You should keep the nose end pointed downward after you disconnect from the adapter.

First make sure the truck cannot possibly pump or dispense fuel while you are checking the strainer and that an inadvertent fuel spill can be caught. Relieve any trapped pressure. Make sure the truck's internal valve, if present, is closed, or if the vehicle is a hydrant servicer, disconnect the hydrant coupler. Make sure that you follow any safety, fire and environmental rules for your company, country or airport location.

IF you can flow the nozzle in a horizontal position and then put it into a bucket or to a test tub without tilting it up, you are fortunate because particles will not fall o'Ut of the strainer. Use this simple procedure. Otherwise, look down 5 paragraphs.

Locate a bucket or other container in a convenient place for the test. Many people simply mount an old 3 lug adapter onto a slop tank,a drum or a tub of some kind. Ready made units are also available (yes,we also have one).

Make sure the bucket (or tub) cannot tip over. One way to do this is to clamp the bucket to something stable. Alternatively, a second person can hold it stable as you do the following procedure.

Either attach nozzle onto a 3 lug adapter, or "trick" open the nozzle interlock if yo have learned how to do it with your fingers. Open the poppet so the nozzle will drain"downhill"into the bucket/tub.

If you are also fortunate enough to have a dry break quick disconnect on the hose, with a built-in valve, the process is simpler and you need to drain less than a gallon of fuel from the nozzle before you detach the quick disconnect to inspect the strainer. You don't have to worry about the hose draining on the ground if you have a dry break quick disconnect.

BUT in many cases, it is impossible to flow the nozzle in a horizontal position and then keep the nozzle in that position

until you check the strainer. If you cannot do this, you usually do not get all the debris into the strainer when you check it.

You will only get the debris stuck in the mesh, but experience shows there will be dirt that falls back into the hose.

For this reason, some experienced QC people and mechanics have developed a method for getting ALL the dirt into the strainer.

As above, locate a bucket or other container in a convenient place for the test. Many people simply mount an old 3 lug adapter onto a slop tank, a drum or a tub of some kind. Ready made units are also available.

Make sure the bucket (or tub) cannot tip over. If need be, one way to do this is to clamp the bucket to something stable. If you use a bucket, a second person can hold it stable as you do the following procedure:

Either clamp the nozzle onto a 3 plug adapter, or "trick" open the nozzle interlock. Open the poppet so the nozzle will drain "downhill" into the bucket tub.

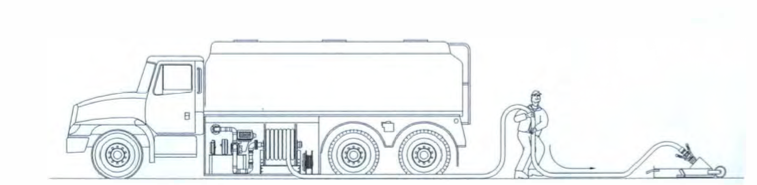

See figure

Now walk to the hose reel and lift the hose Up high, over your shoulder. Walk toward the nozzle, allowing the hose to slide over your shoulder. This is called "walking the hose". This allows fuel in the hose to empty into the bucket tub through the strainer, flushing the debris back into the strainer.

You can now remove the strainer and you will see that visually all the loose debris in the hose is now trapped in the strainer. But you must be very careful with the hose while you are doing this. It MUST be placed with the qui k disconnect higher than the hose reel and other fuel equipment, or the fuel will drain out on the ground once you remove the hose from your shoulder.

If you are fortunate enough to have a dry break quick disconnect on the hose, with a built-in valve, the process is simpler. You don't have to worry about the hose draining on the ground, and so the inspection is much simpler.

All of the above may seem quite simple and logical, but a successful inspection depends on whether o r not you can comply with some words in the first sentence in the fourth paragraph. Here it is again:

"To avoid this problem, the nozzle strainer must be inspected only after flow has taken place with the nozzle in a horizontal position."

If your facility has a test stand, you can probably find a fueling adapter that is horizontal or maybe tilted downward, which is even better. If you do not have a test stand, the refueling truck may have an adapter to which you can connect for recirculation. If you do not have the capacity, the particles that were in the strainer have disappeared, back into the hose somewhere.

What are you going to do? The only thing we can suggest is that you estimate how far back in the hose the particles may be found. For example, if your last refueling was to an aircraft having the fueling adapter 10 feet above ground level, particles maybe 15 or 20 feet from the nozzle. Whatever that distance happens to be is where Person No.2 should lift the hose to "walk" it to the nozzle end. You have to rely upon fuel flowing out of the nozzle to wash the dirt. out of the hose and into the stainer at the same time.