No. 54 OVERFILL AND SPILL PREVENTION APRIL 2003

Does the title sound like a duplication? It is not!! Overfilling an airport refueller surely creates a SPILL, but monumental spills can occur for other reasons. The point we want to make here is that bottom loading control systems, such as the Scully truck loading level control system, are reliable and well-proven to prevent overfills; but they are designed to stop fuel flow going to the truck, not to prevent a spill during other operations of the refueller. That is why NFPA-407, paragraph 5.20.3.4 requires a monthly check to insure complete closure of the bottom loading (internal) valve for each compartment. The Scully system does not do this, because it does not interface with this valve!

Here is an example of an uncontrollable spill, 10,000 gallons on the ramp. A refueller truck is involved in a minor accident that breaks the pipe leading from the bottom loading adapter to the internal valve connection. There is absolutely no way to prevent the entire tank, assuming a single compartment, from draining on the ground if the internal valve has not closed properly. There is no way to stop the flow until the compartment has drained.

Your first point will rightfully be that the internal valve (also known as emergency valve or bottom loading valve) should have been in a closed position, and it is true that if the internal valve had been closed, the spill could not have occurred. But it is a simple fact that internal valves do jam in the open position due to debris, and this is not a rare problem.

Before we look further into the possible and potential problems, let’s review how a typical bottom loading system works.

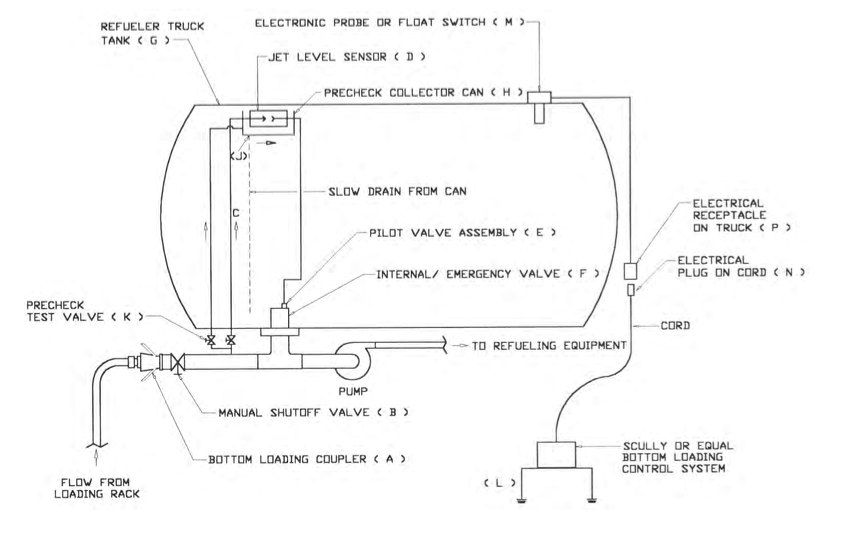

1. The bottom loading coupler is connected at A. Valve B is opened. (refer to diagram on next page) Flow passes through the tubing C connected to the Jet Level Sensor D and applies a force on the pilot E that controls the Internal Valve F. The Internal Valve F now opens to establish full flow into the tank G.

2. If the fuel level rises to cover the Jet Level Sensor D, the force on pilot E will disappear and Internal Valve F will close, thereby preventing an overfill.

3. The operator is instructed to perform a Precheck Test to see whether the Internal Valve F will

close if the force on pilot E is eliminated. A small can H with a small drain hole J surrounds the

Jet Level Sensor D. To perform the precheck, he briefly opens valve K to divert some fuel to fill the

cup H, thereby simulating a full tank. The jet is supposed to pass through a gap to create the

force on pilot E but with fuel in the cup and in the gap, the jet is destroyed so no force is applied

to the pilot.

4. The Internal Valve then closes, stopping flow, proving to the operator that the system is functioning correctly and that the Internal Valve has closed. He then closes the Precheck Valve K, the cup H drains, the jet is re-established to provide a force on the pilot E, permitting the Internal Valve to open so that the tank filling operation can be safely completed.

5. A second overfill protection system is controlled from the fill stand L. The Scully (or equal) apparatus employs an electronic sensor M that is positioned in the truck tank. An electric cable connection N is made between the fill stand control L and a receptacle P on the truck. When the fuel level reaches the sensor M, an electronic signal results in the fill stand control L signaling a valve to close or a supply pump to stop. This is a near foolproof way to prevent overfill.

Clearly, if the precheck test is not performed, the operator will never know that the Internal Valve will not close. This is why operators must be instructed that the precheck test is essential to test the proper functioning of the Internal Valve, not to simply check for overfill protection. Some of you may think that operating the energy stop is testing the Internal Valve, but it is not a proper test. This is because on modern trucks the emergency stop also operates the deadman (in line) valve which closes faster, so you will never know if the Internal Valve also closes.

In conclusion, what could be better than having dual overfill protection? Never forget to include the precheck test to gain the knowledge that the Internal Valve will really close.