No. 36 IS IT PRESSURE OR IS IT FLOW CONTROL? AUG 1989

The fuel pressure that reaches the aircraft is simply a matter of how much a valve has been opened. Right?

But how much a valve is open controls flow rate! Right?

Then how can the same control valve regulate downstream pressure and also the rate of flow? This question puzzles many people, so we thought this would be a good subject for a GamGram.

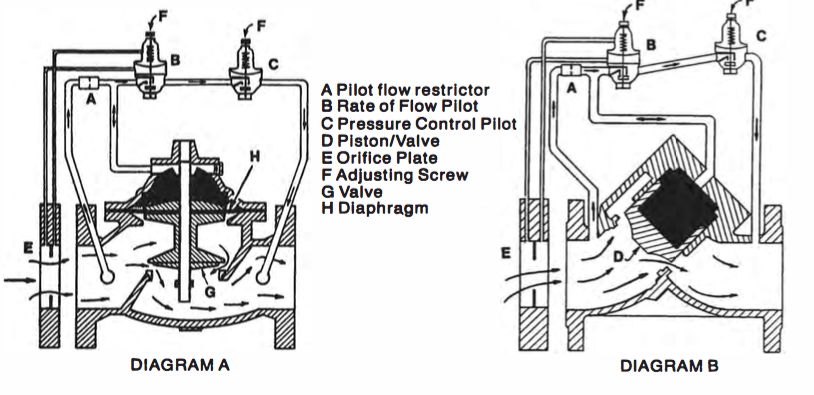

First of all, let's review how a control valve works. Diagram A shows the conventional diaphragm valve made by many manufacturers,_ such as Cla-Val, Muesco, OCV, Smith etc.. Diagram B shows the same valve in piston configuration which is made by Brooks/Brodie and Parker/Thiem. Diaphragm and piston valves both work the same way so we will select only one, the diaphragm type, for this discussion.

The only action a control valve can take is to open or close. How much the valve is open is totally dependent on how much fuel is trapped above the diaphragm or piston (see the shaded area). Therefore, if the cavity above the diaphragm has the maximum amount of fuel in it, caused by upstream pressure being directed there, The diaphragm is forced downward and the valve G is closed (or valve D in the piston version). However, if you permit a small amount of that fuel to be bled off to the downstream side, the valve will open slightly. If you allow the cavity to be. completely vented to the downstream side, the valve opens wide.

How does the valve maker cause this to happen? He uses small auxiliary valves called "pilots". A pilot flow restrictor A reduces inlet pressure depending on how much pilot flow is permitted by the pilot valves B and C. As pilot flow Increases, the lower the pressure on the main valve diaphragm. If pilot flow is stopped, full inlet pressure will bear on the diaphragm to close it. The pilots simply regulate how much of the inlet pressure is applied to the top of the diaphragm by Increasing or decreasing pilot flow and by bleeding off some of the fuel from the shaded area.

A pilot 8 senses the flow rate by measuring the pressure drop across an orifice plate E. The greater the flow, the greater the pressure difference across the orifice. Tubing connections are located upstream and downstream of the orifice plate. These 2 pressures are compared across a diaphragm that has a stem connected to a valve. If this pilot diaphragm moves

because of a change in pressure drop, the valve connected to the stem opens or closes to regulate the amount of pilot flow, and therefore, the amount of fuel above the diaphragm H in the main valve. This regulates the flow rate through the main valve. Actually, the rate of flow pilot is named incorrectly by all manufacturers; it should be called a "flow limiting pilot" because it simply prevents flow from exceeding a desired limit. This can be adjusted by turning a screw F that regulates the spring force on the pilot diaphragm. Think of it this way ; the spring force makes up the difference between the 2 pressures (upstream and downstream) of the orifice plate.

The pilot C is also usually a diaphragm valve that senses the pressure downstream of the main valve and compares it to the force of a spring that Is on the other side of its diaphragm. Just as in the rate of flow pilot, there is a stem connected to the diaphragm that adjusts a valve that is connected to it.This valve regulates the amount of fuel above the diaphragm in the main valve by regulating the flow rate through the pilot fuel restrictor. Therefore, if more pressure is required, the pilot valve opens slightly to let more fuel leave the space above its diaphragm. This allows the main valve to open a bit to build the downstream pressure to the desired level. If downstream pressure gets too high, the pressure pilot closes slightly, preventing escape of fuel from above the main valve diaphragm, forcing the main valve to close slightly, and therefore, reducing down stream pressure.

The question we posed at the start was, "How can the same valve control pressure and rate of flow"? The answer is that the manufacturer arranges the 2 pilots In series with the rate of flow pilot first, as shown in the diagrams. Therefore, If the flow rate Is below the desired level, the rate of flow pilot will open to allow more pilot flow, thereby decreasing the volume above the main valve diaphragm to allow the main valve to open more.

The pilot flow proceeds to the pressure control pilot. If the downstream pressure Is less than desired, it opens to allow more pilot flow, just as the rate of flow pilot did. However, the rate of flow pilot Is in command because it already has opened to allow main stream flow. Therefore, if the pressure control pilot opens to cause more downstream pressure when the flow rate Is already at the maximum allowed by the rate of flow pilot, nothing happens. The rate of flow pilot is "the boss". On the other hand, if the downstream pressure is greater than desired, the pressure pilot will close slightly to reduce pilot flow and cause more fuel to fill the space above the main valve diaphragm, causing the main valve to close slightly to reduce downstream pressure. But this also reduces main stream flow rate! So the rate of flow pilot opens more - and more - and more until it is wide open, but the flow rate will not increase because the pressure control pilot is now "the boss".

The remarkable thing about these valves is that they can do many other tasks, simply by use of various pilot valves. For example, they make excellent check valves, fuel level controllers, back pressure regulators, slug and deadman valves. As an example, we regularly use one pressure control valve to control 2 different fueling pressures, simply by use Qf a manual selector valve. One position controls pressure for underwing fueling while the other position provides a much lower pressure for overwing fueling. In addition, we use a solenoid pilot to provide deadman control, only in the underwing mode. All this with one valve!