No.33 HOSE END PRESSURE CONTROL VALVES JULY 1987

Keeping the barnyard gate closed is the surest way to keep a horse from getting away. Think of a Hose End pressure Control Valve (HECV) as the "gate". You could tether the horse to a stake with a rope, but if the rope fails, the horse leaves through the open gate. Think of the "rope" as the on-boa pressure control valve of the refueling vehicle. The majority

of equipment specifications today require that there be two separate fueling pressure controls; one backs up the other in case of a failure. The gate plus the rope gives better odds! The HECV valve is clearly the least expensive of all pressure control devices on the market and has become very popular as a second control.

The HECV came into use in the 1960's when fueling rates were increasing and the industry

recognized that it had really not paid enough attention to pressure control, and in particular, prevention of pressure surges at the aircraft. The first product on the market was

a massive fueling nozzle having an integral pressure control device. This rather complex

device gave way shortly to the relatively simple HECV that we know today. There are at

least four versions available today; we will restrict this essay to the most popular variety

which i s made by both J.C. Carter Co. and Thiem Industries (formerly Parker).

Before we describe how they work, there is one thing we must get straight. If you want to

measure something (length, pressure, weight, light, etc.), you must have a reasonable

starting point, a "base-line", a datum. You would not measure your height by starting with

your nose! If you want to measure a pressure in a fuel system, the only logical starting

point or datum is atmospheric pressure. If an oil pressure gauge on an engine reads 100

psi, that means 100 psi above atmospheric pressure.

In a fuel system, we must use atmospheric pressure as our "base" or datum. If a HECV valve

is supposed to control at 45 psi, it must be 45 psi above atmospheric pressure. But, how

does the valve know atmospheric pressure? Obviously, we must tell it

this is done in a

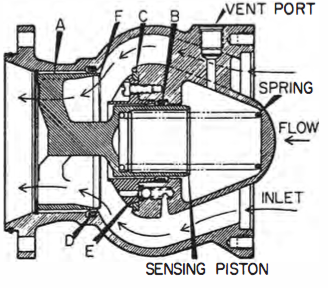

HECV with a Vent Port that will duct atmospheric pressure to one side of a piston. See

drawing. If fuel pressure is on the other side of it, we have "created" a pressure measuring

device. By using a spring on the low pressure

side, the fuel pressure is measured by how much

the spring is compressed.

Now, with the matter of a base-line established,

we see in the drawing that the more the Sensing

Piston moves in compressing the spring, the

smaller is the passageway for fuel to pass

through between the lip F and the seal C The

outer ring A 1 inch is attached to the Sensing

Piston with cross webs, is often called the

"outer piston", but it is clearly not a piston.

As there is no proper word, think of it as a

"cookie cutter" -- it literally shears the

fuel stream! It creates a pressure drop. The

more it cuts off the fuel flow, the lower the

downstream pressure.

Now that the action of the HECV valve is understood, what do you think of an operator who puts a plug in the vent port "because it leaked"? It has really happened! The HECV valve then became inoperative because it had no way to sense atmospheric pressure. What should have been done was the replacement of the seal B.

Back in the first paragraph, we talked about the horse in the barnyard and how the HECV could be thought of as the gate. Then we said that a tether rope could be considered as the on-board pressure control valve. Periodically, we must check the performance of both valves. It is not very difficult to check the HECV because all you need is a pressure gauge in the side port of the nozzle or on a fitting just downstream.

Think about how you can check the truck's on-board control valve. This is more difficult because there is no convenient port to mount a pressure gauge. What we must do is simulate a condition of failure_ of the HECV and then see if nozzle pressure would be con trolled by the on-board valve alone. A simple way to do this is with a tube having quick disconnects on both ends. See Bulletin 75-47. It is called a Block-Out Device. All it does is provide you with a way to temporarily put fuel pressure at the Vent Port to keep the piston from sensing atmospheric pressure. With fuel pressure on both sides of the piston, the HECV is prevented from operating. Unfortunately, this simple test method creates an aggravation -- it makes the normally dry vent port be wet with fuel. So after this test, it is a good idea to cycle the HECV several times to blow fuel out from behind the piston; this avoids false reports that the HECV is leaking.

Which brings us to the question of how to determine if the spring has lost some of its force or if any of the seals in the HECV need replacement. Clearly, if seal B leaks, we can easily see fuel leaking from the vent port. But how do you test seals C and D? This requires a pressure gauge in the side port of the nozzle -- or in the downstream piping of a test stand. The best way to run these tests is with a piston-type hand pump because it allows you to increase pressure very slowly. A hose tester serves this purpose, but only if you connect it upstream of the HECV and downstream of the on-board control valve on the vehicle. As you pump, the hose tester pressure gauge and the nozzle pressure will be very nearly the same until the outer piston reaches seal C. If seals C,D and E do not leak, the pressure in the nozzle should hold at the pressure rating of the spring as you increase the hose tester pressure to 100 or 200 psi. If the nozzle pressure holds at a level more than 3 psi different from the spring setting, you may need a new spring.

Here is where we learn about the pressure relief valve! Many people who have worked with HECV's for years have no idea it is there. What it does is allow the HECV to open again after it has closed. You can check its action in the above test by releasing hose pressure after the test and watching the nozzle pressure gauge. The relief will usually pop open when hose pressure has dropped to about 30 psi below the spring setting.

Now we are at the end of the page, and we still have not mentioned the very best feature of the HECV -- pressure surge control. Here is a simple device, not much larger than your fist. It has one' moving part and no external controls. You mount it on the fueling nozzle where it "can sense instantly that the internal valve of the aircraft has closed. The HECV simply closes -- fast: In test after test that I have witnessed on HECV's, the surge at the aircraft has never gone above 90 psi. Most specifications permit 120 psi as a maximum. Unfortunately, you cannot measure a surge pressure on an airport with common pressure gauges because the mechanism will not respond quickly enough. You may think your gauge shows the surge, but it is telling you a lie. The only way a surge pressure can be measured is with a pressure transducer having high frequency response. The surge is then traced on a recorder.

Failure of the on-board valve or of the hydrant valve may occur in modern systems having ratings of 275 psi, but with 2.3 lbs. of aluminum, you can positively protect the air craft. What a fantastic device!