No. 32 VENTURI AND NOZZLE PRESSURE APRIL 1987 (Revised JAN 1998)

On nearly every refueler truck and hydrant cart which is capable of undegoing (pressure) refueling there is a gauge marked "nozzle pressure". Since it is not connected to the nozzle, how can it really show actual nozzle pressure? There is no magic involved. Actually, it does not show nozzle pressure! What it shows is simulated nozzle pressure. The gauge is connected to a device called a VENTURI. It is usually mounted at the inlet of the hose reel. Few people understand what the venturi does or how to adjust it properly. A large number of the venturis in the world are not properly adjusted.

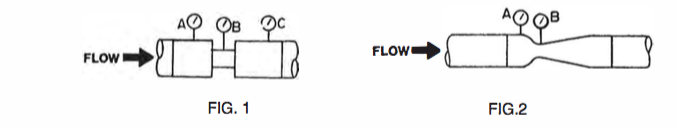

To understand a venturi, we have to understand energy. In a flowing pipe, the energy at any point depends on velocity and pressure. The energy level remains the same except for gradual decreases caused by friction as the fluid passes through valves, fittings and pipe. In Figure1, the pressures at A, Band C will be exactly the same if there is no flow. If flow takes place, the pressure at C will be nearly the same as at A, less a friction loss. However, the pressure at will be much lower than at C. The reason is that we turned some of the pressure energy into velocity energy to get the fluid through the small opening. After the restriction, the velocity energy decreases so the pressure energy must increase accordingly.

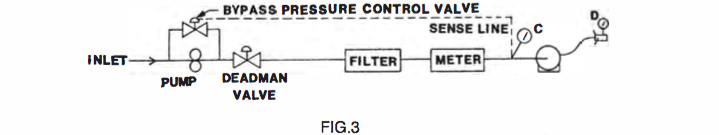

Giovanni Venturi, the Italian scientist, discovered 200 years ago that he could make an excellent flow meter with very little pressure loss if he carefully designed the outlet after the restriction to avoid turbulence and friction. See Figure 2. The pressure recovery zone is a long gradual taper back to the original pipe size. The pressure drop (energy loss due to friction) in his design is much less than in Figure 1.

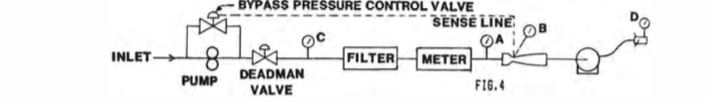

The purpose of a venturi in a fuel system is not to measure flow rate but to provide a simulation of nozzle pressure at Band to use that pressure as the control signal for the pressure control valve. When fuel is pumped to an aircraft, you want maximum flow, but pressure must be kept below 50 psi maximum aircraft fueling pressure to achieve maximum flow rate into the aircraft. See Figure 3. Such a system may require 80 psi at point C in order to result in 50 psi at the aircraft (D), assuming a 30 psi pressure drop in the reel and hose. The problem is that when the aircraft is full, there is no flow and therefore no pressure drop. Without a venturi such a system would, at no flow, put 80 psi on the aircraft. This could cause damage to the aircraft fuel system. If set at 50 psi, the actual fueling rate would be very slow, no where near the design rate because the pressure drop between points C and D would use up much of that 50 psi.

The venturi system (Figure 4) solves this problem. By locating the venturi just before the hose reel, pressure drop across the filter and meter is ignored by the pressure controller. The venturi's job is to compensate for pressure drop in the hose reel, hose and nozzle. As flow increases, the venturi "fools" the pressure control valve into delivering enough pressure so that there is 50 psi at the low pressure point (B). The venturi is "tuned" so that B and D match. Under full flow conditions, supply pressure (C) may be 90 psi and pressure at point A may be 70 psi, but pressure at the nozzle and at point B is 50 psi. When the aircraft is full and flow stops, pressure A, B, C and D return to 50 psi.

ADJUSTMENT OF THE VENTURI

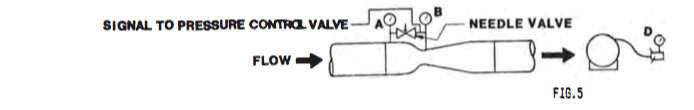

Venturis are not designed to match each system because it would be far too expensive to custom machine each one. Instead, a venturi is selected that has too much compensation. The Whittaker (formerly Thiem) F505 provides up to a 34 psi pressure depression at 600 gpm. If you only need 27 psi of depression to compensate for the pressure drop through the hose reel, hose and nozzle, you must "bleed off" some of the signal. This is done by adjusting a needle valve (Figure 5) so that some fuel from the high pressure zone at the venturi inlet will flow to the venturi throat. The resulting "mixed" pressure signal (27 psi below system pressure) is then fed back to the control valve as its "command". When correctly adjusted, the pressures at gauges B and D read the same. This should be checked at no flow and at full system flow rate.

When properly adjusted, the system allows maximum flow rate without danger to the aircraft. If you change to a different hose length or size (diameter), the venturi must be re-adjusted. We recommend that this adjustment be checked at least once a month. In this way, a possible problem with the pressure control system may be detected and maximum safe flow rate is assured.

* If a hose-end pressure control valve (HECV) is mounted on the nozzle, it must be either removed or "blocked out" to adjust the venturi "nozzle pressure" (See our Bulletin 47). When finished testing the system, remove the block-out device and re-test the system. (The HECV vent will spray some fuel when next used!) Bear in mind that if the HECV is removed for this test, its own pressure drop will not be compensated for by the venturi.

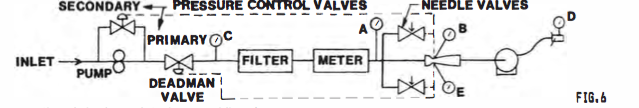

* Most specifications for fueling equipment now require dual pressure controls, one primary and one

secondary or "back up". This can be achieved by various combinations of inline, bypass and hose-end

controls. (We will address this subject in a future Gamgram). A common method has the deadman valve

serve as a primary pressure controller with the bypass valve as a secondary controller. Figure 6 shows how

this is done. Both valves must not be adjusted to control the same pressure because they will "fight" one

another with resulting instability. In any system, the primary regulator controls pressure 5 to 15 psi lower than

the secondary. This may be done either by setting the regulators at different pressures, or by sending the

regulators differently tuned venturi signals. In this example, the in-line (primary) controller is set at 45 psi,

(pressure E). The bypass (secondary) controller is set at 50 psi (pressure B). With this arrangement, if the

aircraft valve closes suddenly, the secondary valve backs up the primary valve by opening quickly to relieve pressure on the primary. (primary pressure may be set as high as 55 psi).

Many systems on refueling trucks use air pressure as a reference using an air pressure regulator. It is a good idea to use a locking regulator (See our Bulletin 70) to prevent unauthorized or "accidental" adjustment. On a Whittaker (Theim) regulator, this will be 16 or 25 psi higher than the desired fuel pressure. This difference is called the "bias" pressure. The purpose of this bias pressure is to allow smooth operation of the controller. To better understand this system, think of it this way: The air reference pressure is on one side of a sensing pilot piston with the venturi pressure on the other side with a bias spring. If the total of spring force and venturi pressure is greater than the air reference pressure, the piston moves slightly toward the air side; this results in the control valve closing slightly to reduce system pressure and make the sensing piston return to a balanced position.