No. 24 SLUG VALVE FLOW AND CONTROL JULY 1981 (Revised September 1989)

We continue to hear arguments about diaphragm operated slug valves. Should they be installed so that flow goes upward through the seat or downward? Should they be located upstream or downstream of the filter separator? Is one safer than another in the event of a diaphragm failure? Can a slug check valve?

Filter separators are most always furnished with three components to provide for automatic water drain and automatic shut-down in the event of a water slug condition. ( Refer to GamGram Nos. 10, 11 and 12. ) The three components are as follows:

Float Control

"Slug" or Discharge Valve

Automatic Water Drain Valve

If there is no water in the filter separator sump, the ball of the float control stays down. If water collects to lift the float to a mid-position, the water

drain valve will open automatically until the water level has dropped. If the water does not drain rapidly enough as in the case of a "slug" of incoming water,

the float rises to a top position and causes the slug valve to close until the water level goes down.

Recognizing that there is controversy on the questions in the first paragraph, we are "throwing down the gauntlet" with a few statements of fact:

IF THE SLUG VALVE DIAPHRAGM FAILS:

1. When the float ball is down or at mid-position and flow is downward through seat, slug valve allows continued flow to some degree.

2. When the float ball is at top position and flow is downward through seat, slug valve closes tight with no downstream leakage.

3. When the float ball is down and flow is upward through seat, slug valve allows substantial flow.

4. When the float ball is up and flow is upward through seat, slug valve allows continued flow to some degree.

The amount of flow that will occur in 1, 3 or 4 depends on the size of a diaphragm rupture. A very small break can result in a rather large valve opening. Obviously, the most dangerous situation is 4. It takes no great mental effort to conclude that we want zero flow in a water slug situation. Therefore, the arrangement shown in GamGram No. 12 is desirable.

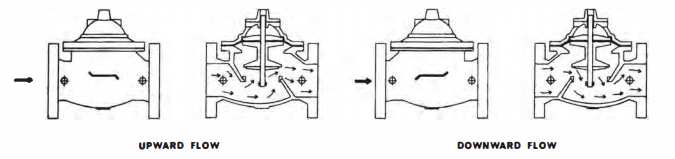

Do you know how to figure out whether your slug valve is flowing upward or downward through the seat? Look at the 3-leg line t:tat is cast in the valve

body. It represents the bridgewall as shown below:

• The 4 statements on the first page are true regardless of whether the slug valve is located upstream or downstream of the filter

separator. They also apply for all brands of diaphragm valves usually found in aviation fuel systems: ClaVal, Baker, Oil Capital, A.O. Smith and Harwood.

• No brand of standard slug valve will function as a check valve whether upstream or downstream of a filter separator, whether operating in one direction or the other, unless the pilot circuit is especially designed to add this feature. Kits are available that will make any slug valve work as an excellent check valve.

• Many installations are being made today with a conductivity probe replacing the float control in the filter separator water sump. The slug valve is then controlled by using a solenoid valve in the pilot circuit. All of the four statements regarding diaphragm rupture also remain true for this type of installation.

OTHER DIAPHRAGM FAILURES:

Some brands open when pilot pressure is directed to the top of the diaphragm. Others open when pilot pressure is vented. See GamGram No. 10 to learn which

type you have.

AUTOMATIC DRAIN VALVES:

a. If pilot pressure is supposed to open the valve, pilot line flow will be vented instead of causing

opening.

b. If the valve is supposed to open when pilot pressure is vented , it will stay closed but water will vent through the pilot lines.

3-WAY PILOT ON SLUG VALVE:

c. If pilot pressure is supposed to cause the slug valve to open, it will stay closed. Leakage through the diaphragm will go downstream.

d. If the slug valve is supposed to open when pilot pressure is vented, it will stay closed. Leakage through the diaphragm will be vented.

As a result of this GamGram, many of our readers will decide to reverse the direction of flow in their slug valves. Before starting such a project, be sure you understand exactly how all of the pilot lines must be re-routed. Contact the manufacturer or one of our representatives for assistance.