This issue is the second in a series that deals with filter separator control valves. In the last issue, No. 10, the emphasis was on the differences among various brands.

NO. 11 FILTER SEPARATOR CONTROLS- PART 2 TESTING AUG.1976 REVISED NOV. 1996

Did you know that to this very day there are oil companies and airlines who never test the control valves on filter separators? If you never test the float pilot valve, how can you know that it will operate if a big slug of water comes along? Are you saying that you never have water anyhow? At this point I make a rude remark and remind you that you have that equipment to save your skin in the event that something unexpected happens.

One of the humorous experiences I have have, in traveling from airport to airport these many years, was with a customer who was vigorously resisting spending money to change long overdue elements in his filter separator, "because we never have water in our fuel". We were standing beside the filter and right after he finished talking, a stream of foul dark water started to gather around his shoes. The automatic water drain valve had opened.

And then there are the operators who put plugs in the outlet ports of their automatic water drain valves. Many of you have manual valves that are kept closed upstream or downstream of the automatic water valve. If you do this to stop leaks, you must realize that you have completely eliminated this factor of safety. In fact, if the vent tube is connected to a plugged drain valve, you will prevent the slug valve from operating correctly. Why not repair the leak? Every manufacturer can supply spare parts with diagrams showing how to replace seals. Or if you do not want to do your own repairs, there are many qualified shops (including ours} that do this work.

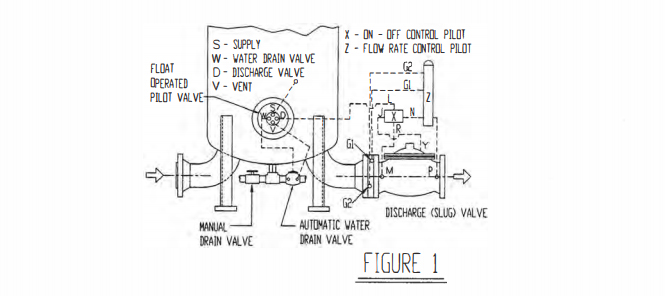

NOTE: In the 1996 revision, this figure has been revised for clarification.

One of the great controversies in the aviation fuel world is whether or not to have an automatic drain valve. Some people have decided to have a float operated pilot

valve and a discharge valve only. In other words, they want flow to stop if water collects. The operator then must manually drain out the water before fuel flow can

begin again. I If you ever wish to deactivate an automatic water drain valve and retain normal operation of the discharge (slug) valve, we offer these words of

caution. The vent ports of all brands of float operated pilot valves must be left open. You must plug ClaVal port W, Brooks Brodie port A, Baker port C2, Oil Capital port W and Smith port 2. (See Gam Gram No. 10 for additional information.) You must completely remove the ClaVal and Brooks Brodie automatic drain valves but you need not do this in the case of other brands.

Do you have float testers on your float operated pilot valves? This handy little gadget is just an 0-ring sealed screw or plunger that you can open to cause the float to go up and down while the system is operating With this device, you can quickly check the automatic drain valve as well as the discharge valve. Almost all models of float operated valves can be equipped with testers. Each manufacturer sells a kit with the necessary parts but on some models you must drill and thread a hole in the valve body.

When did you last test your floats to see if they will float on a fuel/water interface? Many people now perform this test on a regular schedule. There are two procedures in use:

Method 1: A hand pump is used to force water in the manual drain valve. The water is drawn from an open bucket so that you can see exactly how much water is being used. This method will also allow you to test the automatic drain valve and the discharge valve.

NOTE: A mechanic recently decided to run this test by using city water pressure. When I pointed out that the refueler pressure could be greater than the city pressure, he agreed that people might be unhappy at finding jet fuel in their kitchen sinks.

Method 2: Remove the float and drop it in a bucket that has 4 inches (10 em) of fuel on top of 4 inches of water. If the float sinks in the water, you must return it to the manufacturer to be repaired or replaced.

Leakage is by far the most prevalent complaint regarding filter separator controls. Many of these complaints are not fully justified because some people do not

understand that a 11Spit11 of fuel is discharged from the vent every time the system is operated. This is caused by the operation of the diaphragm in the On-Off pilot valve and amounts to only a few drops. Continuous drippinQ is most frequently caused by dirt particles under the seat of the automatic water dra1n valve. This is why many operators require that a Y strainer be located upstream of the drain valve. A very useful device that is often installed in the discharge line from an automatic water drain valve is a flow indicator. Many different models are on the market (pin wheels, flappers, jiQgling balls, etc.). In a drain system that is piped to a waste tank, one of these flow Indicators provides a visual indication of discharge flow.

In the next issue of the GamGram, the discharge valve and its pilot controls will be studied.